In the competitive world of plastic manufacturing, maximizing efficiency is crucial to staying ahead. Efficient processes not only reduce costs but also enhance product quality and sustainability. At Marne Plastics, we understand the importance of fine-tuning operations to achieve peak performance. Here’s a guide to help you optimize your plastic manufacturing processes, reduce waste, and boost overall efficiency.

Upgrading to modern machinery and technology can have a profound impact on your manufacturing efficiency. Invest in high-precision equipment, such as advanced injection molding machines and automated systems, to improve accuracy and reduce cycle times. Incorporate Industry 4.0 technologies, such as IoT sensors and data analytics, to monitor and optimize machine performance in real time.

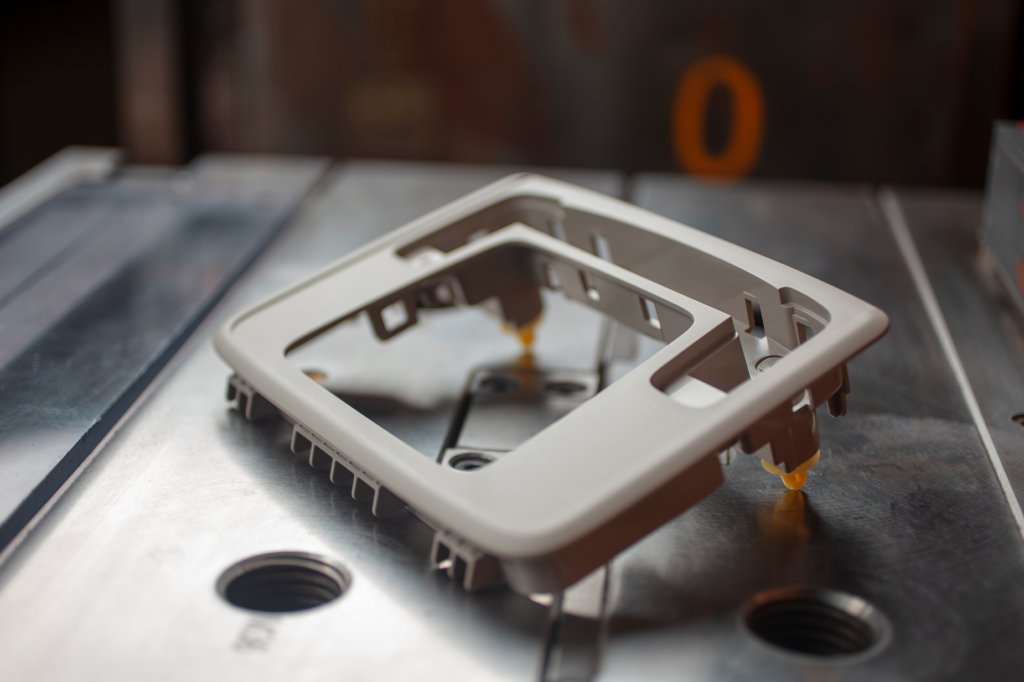

The key to efficient plastic manufacturing lies in optimizing process parameters. Regularly calibrate machines and fine-tune settings such as temperature, pressure, and cooling time. Conduct thorough testing and analysis to determine the ideal parameters for each product. By maintaining consistent process conditions, you can minimize defects and ensure uniform quality.

Adopting lean manufacturing principles can significantly enhance efficiency. Identify and eliminate waste in all forms—whether it’s excess material usage, unnecessary steps in the production process, or idle machine time.

Routine maintenance is essential to prevent unexpected breakdowns and prolong equipment life. Establish a preventive maintenance schedule to regularly inspect and service machinery. This proactive approach helps identify potential issues before they become major problems, reducing unplanned downtime and ensuring continuous production.

Robust quality control measures are crucial for minimizing defects and rework. Implement real-time quality monitoring systems to detect issues early in the production process. Conduct regular inspections and audits to ensure that products meet the highest standards. By addressing quality concerns promptly, you can prevent waste and maintain efficient production flows.

Maximizing efficiency in plastic manufacturing requires a multifaceted approach that combines advanced technology, optimized processes, and a commitment to continuous improvement. By implementing these best practices and tips, you can enhance productivity, reduce waste, and achieve superior product quality. At Marne Plastics, we are dedicated to helping our clients achieve manufacturing excellence and stay competitive in the dynamic world of plastic production.

For more insights and support in optimizing your manufacturing processes, contact Marne Plastics today. Let us help you unlock the full potential of your operations and drive your success forward.