How Marne Plastics Uses Automation to Deliver Better Results

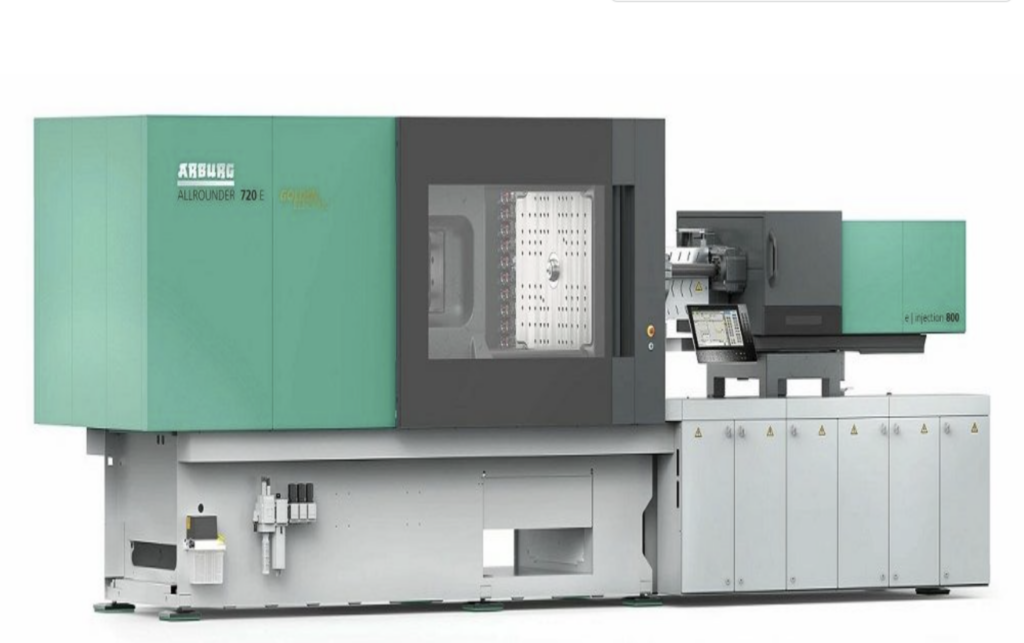

In today’s fast-paced manufacturing world, companies need more than just plastic parts — they need a partner who can deliver high-quality, consistent results with speed, precision, and efficiency. At Marne Plastics, automation is a key part of how we meet those expectations. By investing in advanced molding technology, robotics, and streamlined production systems, we’re able […]

How Marne Plastics Uses Automation to Deliver Better Results Read More »