How We Use Rapid Prototyping and 3D Printing in Plastics Molding

In recent years, rapid prototyping and 3D printing have emerged as transformative technologies in the plastics molding industry, revolutionizing the way products are designed, developed, and manufactured. Rapid prototyping refers to the swift creation of physical models from computer-aided design (CAD) data, enabling designers and engineers to produce prototypes in a matter of hours or days.

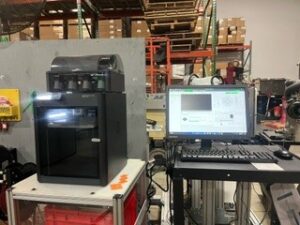

Marne Plastics has added rapid prototyping and 3D printing to the value-added services we provide our clients. This accelerated process significantly reduces the time-to-market for new products, allowing companies to innovate and respond to market demands more effectively. One of the key advantages of rapid prototyping is its flexibility; designers can easily modify and iterate on their designs, ensuring that the final product meets specifications and user needs without the extensive tooling and setup costs associated with traditional manufacturing methods.

Marne Plastics has added rapid prototyping and 3D printing to the value-added services we provide our clients. This accelerated process significantly reduces the time-to-market for new products, allowing companies to innovate and respond to market demands more effectively. One of the key advantages of rapid prototyping is its flexibility; designers can easily modify and iterate on their designs, ensuring that the final product meets specifications and user needs without the extensive tooling and setup costs associated with traditional manufacturing methods.

3D printing, often synonymous with additive manufacturing, plays a crucial role in rapid prototyping. This technique involves creating three-dimensional objects layer by layer from digital files, which allows for the production of complex geometries and intricate designs that traditional methods struggle to achieve. Common 3D printing techniques, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), offer a range of capabilities suited to different applications. The benefits of 3D printing in plastics molding are numerous, including the ability to use a variety of plastic materials—such as ABS, PLA, and Nylon—and the reduction of waste by utilizing only the necessary amount of material.

The applications of these technologies are vast. In product development, rapid prototyping facilitates quick iterations, helping companies refine their designs and align them with market needs. Additionally, 3D printing enables the production of custom parts, tailored to specific requirements, making it an ideal solution for low-volume manufacturing without the expense of creating molds. Tooling and fixtures can also be produced more efficiently, enhancing manufacturing processes and improving overall accuracy.

Please contact us to learn more about Marne Plastics’ rapid prototyping and 3D printing services.